Choose the Right Dolly

Ensure that the platform dolly you're using is strong enough to handle the load you plan to transport. Check the weight capacity of the dolly and compare it with the weight of the item. Always opt for a dolly with a slightly higher capacity than required for added safety.

Position the Dolly

Place the dolly flat on the floor, making sure that it is stable and on a level surface. If you're moving the dolly across carpet or uneven ground, consider using one with larger, rubberized wheels for better maneuverability.

Load the Dolly

Position the item you intend to move onto the platform carefully. For larger items, lift them using proper lifting techniques (bending your knees, not your back). If the item is heavy, ask for assistance to lift and place it onto the dolly.

Secure the Load

If needed, secure the item with straps or bungee cords to prevent it from shifting during transit. This is particularly important when moving items like furniture that might slide off the dolly during transportation.

Move the Dolly

Once the load is secured, gently push or pull the dolly to its new destination. Use smooth, controlled motions to avoid sudden jerks or tilts. Always maintain an upright posture and avoid overloading the dolly.

Unloading

When you reach your destination, carefully unload the item from the dolly. Use proper lifting techniques again, especially if the item is large or bulky.

The platform wood dolly truck has evolved significantly over the years, from simple wooden structures to sophisticated, industrial-grade tools used in warehouses, factories, and homes. The concept of a moving dolly dates back to the early 19th century when wooden carts were first used to move heavy loads in construction and trade. These early designs were simple, rectangular platforms with basic wheels, often pulled by hand or horse.

As industrialization grew in the late 1800s and early 1900s, the need for more efficient material handling increased. Manufacturers began experimenting with improved materials and wheel designs. By the mid-20th century, platform dollies made of plywood or solid wood were widely used in furniture moving, and they started to feature heavier-duty wheels for smoother transportation.

In the modern era, wood platform dollies have been refined for greater strength and durability. Today, they often come with reinforced corners, larger, more maneuverable wheels, and ergonomic handles. While the basic concept of a flat platform has remained largely the same, the development of materials like rubber and steel has allowed for the creation of lighter, more reliable moving dollies. These innovations have made wood platform dollies an indispensable part of logistics, moving, and even home decor transport.

Platform wood dolly trucks have evolved over time in response to changing material-handling needs, workplace environments, and manufacturing capabilities. Their development reflects a balance between simple construction, load-bearing performance, and practical mobility. The following table outlines key stages in the historical development of platform wood dolly trucks, followed by explanatory discussion.

|

Development Stage |

Time Period |

Key Characteristics |

Practical Significance |

|

Early Manual Dollies |

Late 19th – early 20th century |

Solid wood platforms, no wheels or basic iron rollers |

Enabled short-distance movement of heavy goods |

|

Introduction of Wheeled Platforms |

Early–mid 20th century |

Wooden platforms with steel or cast-iron wheels |

Improved mobility and reduced manual lifting |

|

Standardization and Industrial Use |

Mid 20th century |

Standard sizes, improved wheel bearings |

Supported warehouses and factories |

|

Material and Design Optimization |

Late 20th century |

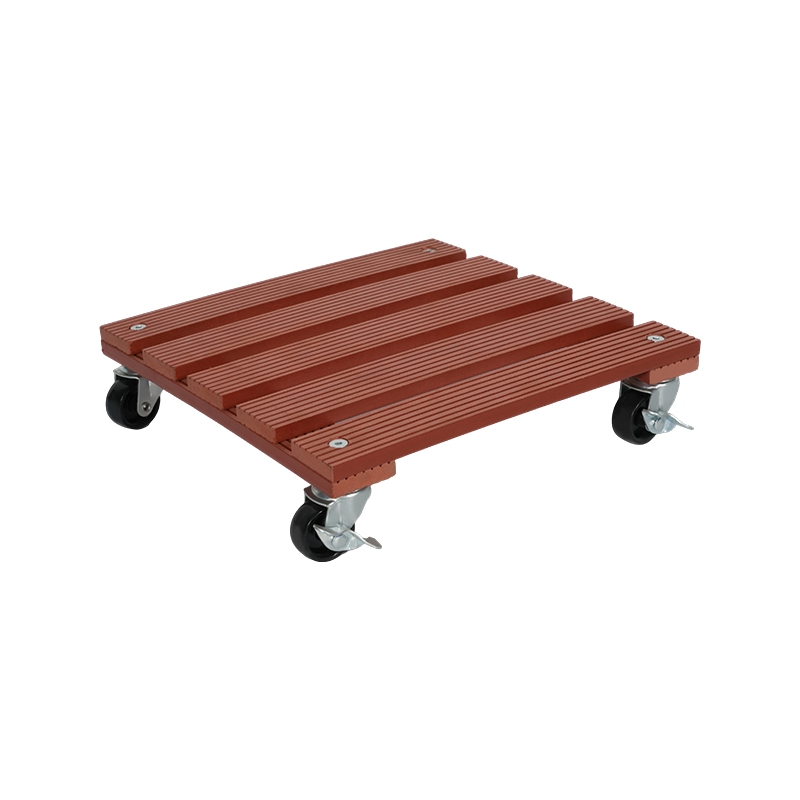

Plywood/MDF platforms, rubber or PU wheels |

Better floor protection and handling efficiency |

|

Modern Functional Adaptations |

21st century |

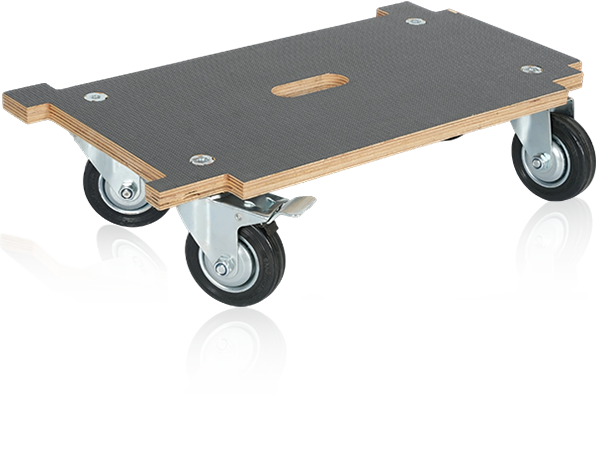

Reinforced wood, swivel casters, ergonomic layouts |

Adapted to diverse logistics and retail needs |

The earliest forms of platform dollies were simple wooden boards used to slide or lever heavy loads across floors. These early tools relied heavily on human strength and basic physics rather than mechanical assistance. While they reduced the need to lift items completely, movement was still slow and required multiple operators. Their significance lay in introducing the idea of load distribution across a flat surface.

As industrial activity increased, the addition of wheels marked a key transition. Early wheeled platform wood dolly trucks used metal or cast-iron rollers mounted directly beneath wooden platforms. This allowed loads to be moved more smoothly over warehouse floors and paved surfaces. Although maneuverability was limited, these designs significantly reduced physical strain and improved handling efficiency.

During the mid-20th century, growing factory and warehouse operations led to greater standardization. Platform sizes, load ratings, and wheel configurations became more consistent. Improved bearing technology reduced rolling resistance, making dollies easier to control. At this stage, platform wood dolly trucks became a common fixture in logistics, manufacturing, and distribution environments.

Later developments focused on optimizing materials. Solid wood was increasingly replaced or reinforced with plywood or MDF to improve dimensional stability and reduce weight. Wheel materials evolved from metal to rubber and polyurethane, improving noise control and floor protection. These changes made platform wood dolly trucks more suitable for indoor commercial and retail environments.

Today’s platform wood dolly trucks incorporate reinforced frames, swivel casters, and anti-slip surfaces. While the core concept remains unchanged, modern designs address ergonomic concerns, safety expectations, and diverse usage scenarios. This evolution demonstrates how a simple handling tool has adapted over time while maintaining its fundamental practicality.

Manufacturing a 4-wheel furniture dolly involves several key steps that ensure the final product is strong, reliable, and suitable for heavy-duty use. Below is an outline of the typical manufacturing process:

Design and Planning

The first step is to design the dolly. Engineers decide on dimensions, weight capacity, and material specifications based on the intended use. The design includes measurements for the platform, wheels, and frame. CAD (computer-aided design) software may be used to create the blueprints.

Material Selection

The next step involves selecting the appropriate materials. Wood, usually plywood or hardwood, is chosen for the platform, while strong metal or durable plastic is selected for the wheels. Quality control is essential during this phase to ensure that the materials can handle the required load and are built to last.

Cutting the Platform

Using the specifications from the design phase, the wood is cut into the necessary shapes for the dolly's platform. This process involves precision cutting using saws or CNC machines to ensure the edges are smooth and the platform is uniform.

Frame Assembly

Once the platform is cut, the frame is assembled. The frame typically includes four legs (or supports), and the platform is attached to these supports using screws or bolts. Reinforcements may be added to ensure the dolly can handle heavier loads without collapsing or warping.