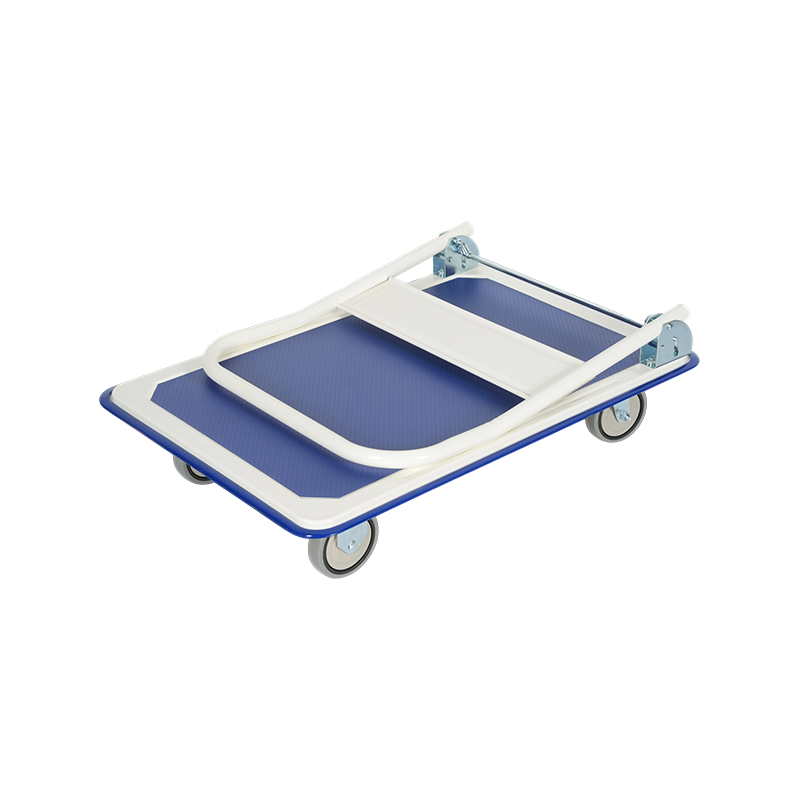

An MDF folding trolley is a mobile handling device that combines a foldable metal frame with a medium-density fiberboard (MDF) platform. It is commonly used in warehouses, offices, retail environments, workshops, and light industrial settings for moving cartons, tools, supplies, and equipment over short distances. The defining features of this type of trolley are its collapsible structure and its MDF load surface, which together support space efficiency and functional versatility.

Unlike fixed platform carts, MDF folding trolleys are designed for users who require occasional mobility without dedicating permanent floor space to handling equipment. When not in use, the handle or frame folds down, allowing the trolley to be stored against a wall, under shelving, or in a vehicle. This makes it suitable for environments where storage space is limited or usage patterns vary.

Structural Design and Construction Features

The structure of an MDF folding trolley is engineered to balance stability, portability, and durability. While designs may vary by manufacturer, several common construction features are typically present:

Metal Frame Support

The frame is usually made from steel tubing or reinforced metal sections that provide structural integrity. This frame supports the MDF platform and transfers load forces to the wheels.

MDF Load Platform

The platform is manufactured from medium-density fiberboard, which offers a flat, uniform surface. MDF provides consistent thickness and strength, making it suitable for boxed or evenly distributed loads.

Folding Handle Mechanism

The handle is connected through hinges or locking joints that allow it to fold flat against the platform. Locking mechanisms secure the handle in the upright position during use.

Caster Wheel Configuration

Most MDF folding trolleys use four wheels, often with a combination of swivel and fixed casters to improve maneuverability and directional control.

This structural combination allows the trolley to perform reliably in everyday handling tasks while remaining easy to store and transport.

Medium-density fiberboard plays a central role in defining the performance characteristics of this type of trolley. MDF is manufactured from wood fibers bonded under heat and pressure, resulting in a dense and uniform board.

Key material characteristics include:

Even Load Distribution

MDF provides a smooth, flat surface that distributes weight evenly across the platform. This reduces point loading and improves stability when transporting boxes or containers.

Dimensional Consistency

Unlike some natural wood panels, MDF does not have grain variation, which helps maintain consistent thickness and surface quality.

Surface Finish Compatibility

MDF platforms can be laminated, coated, or sealed to improve moisture resistance and wear performance, depending on the intended environment.

While MDF is not intended for prolonged outdoor exposure or heavy moisture conditions, it performs well in indoor and controlled environments where flat support surfaces are required.

Load Capacity and Performance Considerations

The load capacity of an MDF folding trolley depends on the combined strength of the MDF platform, metal frame, and caster wheels. Typical models are designed for light to medium-duty transport tasks.

Performance considerations include:

Rated Load Capacity

Many MDF folding trolleys are rated between 150 kg and 300 kg, depending on platform thickness and frame reinforcement. Users should always refer to manufacturer specifications.

Dynamic vs. Static Loads

Movement introduces additional forces. Operating within recommended capacity margins helps maintain stability and prolong service life.

Wheel Quality Impact

Wheel diameter, material, and bearing type significantly influence rolling resistance and load handling performance.

For best results, loads should be evenly distributed across the platform rather than concentrated at a single point.

An MDF folding trolley offers several practical advantages that make it suitable for a wide range of applications:

Space-Saving Design

The folding mechanism allows compact storage when not in use, which is valuable in space-constrained environments.

Flat and Stable Platform

The MDF surface supports cartons, crates, and equipment without gaps or uneven contact points.

Ease of Handling

Lightweight frame construction combined with rolling casters reduces physical strain during transport.

Cost-Effective Construction

Compared with solid wood or all-metal platforms, MDF provides a balance between performance and cost efficiency.

Versatile Usage Scenarios

Suitable for offices, retail backrooms, warehouses, schools, and event setups.

These advantages make MDF folding trolleys a practical solution for organizations seeking flexible material handling equipment.

Unlike basic flat carts, this type of dolly is designed with layered support structures and moisture-resistant materials. These features allow it to perform reliably in environments where humidity, spills, or outdoor movement may occur. Understanding how it works, what problems it solves, and where it fits best can help users make informed decisions about its application.

A waterproof multi-layer board dolly is a mobile platform designed to transport stacked boards vertically or horizontally while maintaining separation, stability, and moisture resistance. The “multi-layer” aspect typically refers to tiered or framed support structures that prevent boards from shifting or bending during movement.

The “waterproof” characteristic is achieved through treated panels, sealed surfaces, plastic composites, or coated metals that resist water absorption and corrosion. This makes the dolly suitable for environments where materials might be exposed to damp floors, rain during transport, or wash-down conditions.

Key functional goals of this dolly include:

Although designs vary, most waterproof multi-layer board dollies share similar structural elements. The following table outlines common components and their functions:

|

Component |

Description |

Functional Purpose |

|

Frame |

Steel or aluminum structure with protective coating |

Provides load-bearing strength |

|

Multi-layer supports |

Slots, rails, or dividers |

Keeps boards separated and upright |

|

Waterproof panels |

Treated wood, plastic, or composite |

Resists moisture absorption |

|

Caster wheels |

Swivel or fixed, often sealed bearings |

Enables smooth movement |

|

Protective edges |

Rubber or polymer bumpers |

Reduces board edge damage |

This layered structure allows boards to be stacked in an organized manner, reducing the risk of sliding or uneven pressure that could cause deformation.

A common question users ask is: Why does waterproofing matter for a board dolly?

The answer depends on the materials being transported and the working environment.

Boards such as MDF, plywood, or laminated panels are sensitive to moisture. Even brief contact with water can lead to swelling, delamination, or surface damage. A waterproof dolly helps mitigate these risks by: