What Is a Hardware Display Stand?

A hardware display stand are commonly found in retail environments such as hardware stores, building supply outlets, and tool showrooms, but they are also used in warehouses, exhibitions, and industrial facilities. Their primary function is to display items such as fasteners, tools, fittings, hinges, or accessories in a way that supports visibility and efficient selection.

From a structural perspective, hardware display stands are typically manufactured from metal, wire mesh, or reinforced plastic, depending on load requirements and usage conditions. Metal display stands are frequently chosen for heavier items due to their stability and durability, while modular designs allow shelves, hooks, or bins to be adjusted based on product size and quantity. This adaptability helps businesses respond to changing inventory without replacing entire display systems.

In addition to storage and presentation, hardware display stands contribute to operational efficiency. Well-organized displays reduce the time customers or staff spend locating items, which can improve service flow and reduce handling errors. Clear labeling areas and standardized layouts also support inventory management and restocking processes.

From a commercial standpoint, display stands help create a structured and professional retail environment. By grouping related products and presenting them at accessible heights, these stands support informed purchasing decisions. Overall, a hardware display stand is not simply a storage solution, but a functional tool that balances organization, accessibility, and durability in hardware-focused environments.

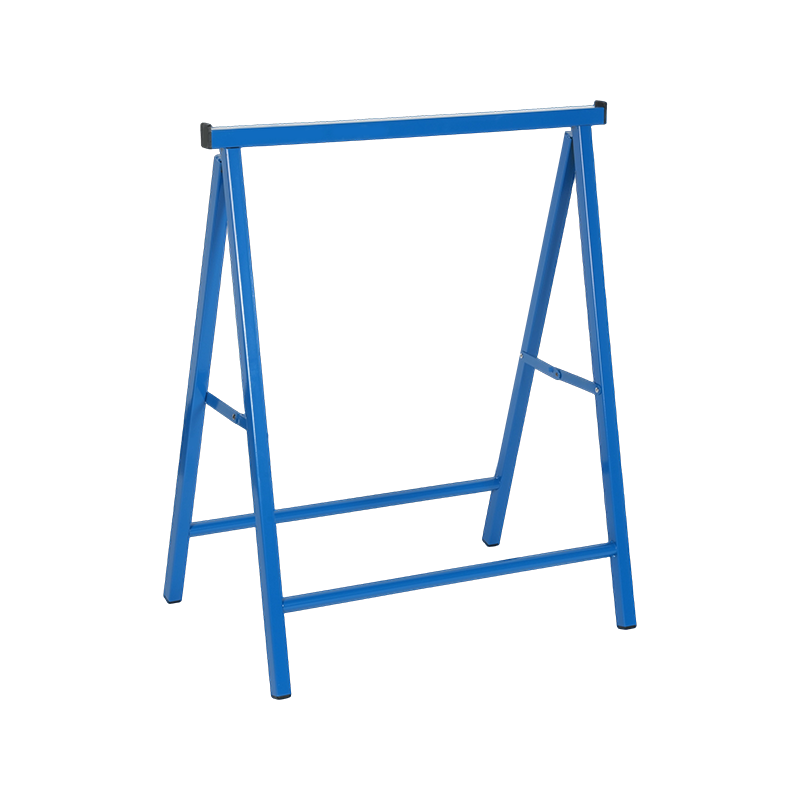

Are Heavy Duty Metal Saw Horses Better Than Wooden Ones?

Heavy duty metal sawhorses and wooden sawhorses each serve practical roles, but their performance differs depending on usage demands. Metal sawhorses are generally designed for professional and industrial applications where strength, consistency, and longevity are important. They are often manufactured from steel or aluminum and feature reinforced frames that support higher load capacities than wooden alternatives.

One advantage of metal sawhorses is structural consistency. Unlike wood, metal does not warp, split, or weaken due to moisture exposure or repeated load cycles. This makes metal sawhorses suitable for construction sites, fabrication shops, and outdoor environments where conditions may vary. Many models also include non-slip feet, locking mechanisms, or adjustable height features that improve stability and usability.

Wooden sawhorses, by contrast, are commonly used for lighter-duty tasks or temporary setups. They are often less expensive and can be easily built or repaired on-site. However, their load capacity and lifespan depend heavily on wood quality, joint construction, and environmental exposure. Over time, wooden sawhorses may loosen at joints or degrade if used frequently under heavy loads.

That said, metal sawhorses are not universally better for every scenario. They may be heavier, less customizable on-site, and more costly upfront. The choice ultimately depends on expected load, frequency of use, and working environment. For repeated, demanding tasks, heavy duty metal sawhorses tend to provide more consistent performance, while wooden options remain suitable for lighter or occasional work.

How to Choose Industrial Steel Sawhorses & Work Horses?

Selecting industrial steel sawhorses and work horses requires careful consideration of functional and operational requirements. The following points provide guidance for making an informed choice:

- Load Capacity Requirements

Evaluate the weight the sawhorses will support, including materials and tools. Choose models with rated capacities that exceed expected loads to allow for safety margins.

- Frame Construction and Material Thickness

Look for reinforced steel frames, welded joints, and adequate material thickness. These factors directly influence stability and resistance to deformation.

- Stability and Safety Features

Non-slip feet, cross-bracing, and locking mechanisms help prevent movement during use. These features are particularly important in industrial environments.

- Portability and Storage

Consider whether folding or stackable designs are needed for transport and storage. Portable designs are useful for job sites with limited space.

- Height and Adjustability

Fixed-height sawhorses suit standardized tasks, while adjustable models provide flexibility for different working heights and applications.

- Environmental Conditions

For outdoor or humid environments, corrosion-resistant coatings or galvanized finishes can extend service life.

- Compatibility with Work Surfaces

Some industrial work horses are designed to support beams, panels, or temporary worktops. Ensure compatibility with planned applications.

English

English 中文简体

中文简体