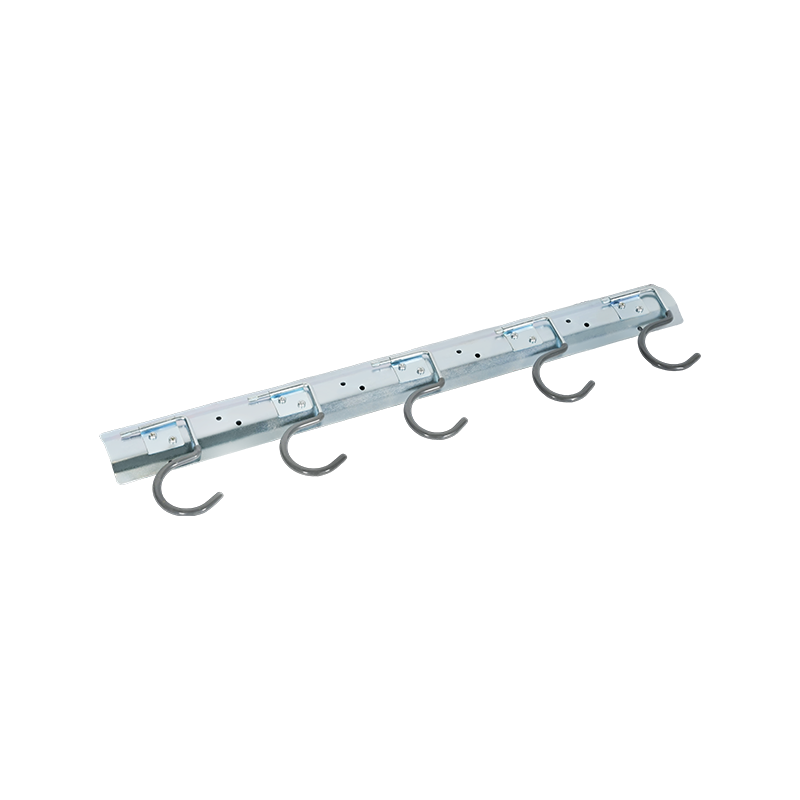

What are metal tool hooks commonly used for?

Metal tool hooks are primarily used to hang and organize tools, equipment, and accessories in garages, workshops, warehouses, and utility rooms. Their rigid structure allows them to support items such as hand tools, power tools, ladders, hoses, and garden equipment. By utilizing vertical wall space, metal tool hooks help reduce floor clutter and improve accessibility. This arrangement allows users to locate and retrieve tools quickly, which supports more efficient workflows in both residential and professional environments.

Why are metal tool hooks preferred over plastic alternatives?

Metal tool hooks are often selected because of their higher load-bearing capability and resistance to deformation. Compared with plastic hooks, metal versions are less likely to bend or crack under sustained weight. They also perform more consistently in environments where temperature changes, humidity, or frequent use are factors. With appropriate surface treatments, metal hooks can resist corrosion and wear, making them suitable for long-term use.

How should metal tool hooks be installed for safe use?

Proper installation is essential for safe and reliable performance. Metal tool hooks should be mounted into wall studs, masonry, or reinforced panels using suitable screws or anchors. Load limits provided by manufacturers should be observed, and heavier items should be distributed across multiple hooks if necessary. Correct spacing between hooks also helps prevent tools from colliding or slipping during placement and removal.

The Practical Role of Garage Storage Hooks

Garage storage hooks are designed to address the common challenge of limited space in residential and light commercial garages. These hooks enable users to store items vertically, making use of wall areas that might otherwise remain unused. This approach is especially helpful for storing bulky or irregularly shaped items such as bicycles, extension cords, sports equipment, and yard tools.

One of the key benefits of garage storage hooks is improved organization. When tools and equipment are clearly visible and individually hung, users can quickly assess what is available and what may be missing. This visibility reduces time spent searching for items and supports more orderly storage habits. Over time, this can contribute to better maintenance of tools, as items are less likely to be damaged by stacking or improper storage.

Garage storage hooks also contribute to safety. Keeping equipment off the floor reduces tripping hazards and allows for clearer walkways and parking areas. For households with children or pets, wall-mounted storage can help keep sharp or heavy tools out of reach. In addition, hooks designed with protective coatings or rounded edges can minimize wear on tool handles and cables.

From a flexibility standpoint, garage storage hooks are available in various sizes and shapes to accommodate different storage needs. Many systems allow hooks to be repositioned along tracks or panels, enabling users to adapt layouts as storage requirements change. This adaptability makes garage storage hooks a practical solution for evolving household or workshop needs.

What Are the Common Materials for Tool Hooks 6 Pack?

Tool hooks sold in multi-piece packs, such as a tool hooks 6 pack, are typically manufactured from materials selected for strength, durability, and cost efficiency. Common material options include:

Carbon Steel

Carbon steel is widely used due to its high strength and load-bearing capacity. It is suitable for heavy tools and equipment when combined with proper wall mounting.

Stainless Steel

Stainless steel offers good corrosion resistance, making it appropriate for humid environments or semi-outdoor use. It is often chosen for applications where long-term appearance and resistance to rust are important.

Alloy Steel

Alloy steel hooks are engineered for enhanced toughness and fatigue resistance. They are commonly used in professional or industrial-grade storage solutions.

Powder-Coated Steel

This material combines steel strength with a protective powder coating that improves corrosion resistance and reduces surface wear. The coating also helps prevent scratches on stored tools.

Rubber- or PVC-Coated Metal

Some tool hooks feature a metal core with a rubber or PVC coating. This provides additional grip and protects tool surfaces from abrasion while maintaining structural support.

English

English 中文简体

中文简体